Dealey Pest Control

Environmental Protection of Property and Product

CALL 01359 269713 Customer PortalDealey Pest Control

Environmental Protection of Property and Product

CALL 01359 269713 Customer PortalPeople often get themselves confused with the terminology around fumigation.

This is the best definition of fumigation that we have come across:

"Fumigation is the measured process of application, exposure and dissipation of a toxic chemical in its gaseous state with the purpose of control of target pests in a product or enclosure."

The definition can be attributed to the great international fumigation trainer of the 1990s and 2000s, Mike Kelly who did his best to ensure raised fumigation standards around the globe

(L)Mike Kelly, Head of Acheta and (R) Martin Cobbald, MD of Dealey Environmental. Despite appearances, they are unrelated.

The first thing to note from this definition is that we are using gasses. Many people confuse many different pest control methods with fumigation. Smokes, thermal fogs, ULV fogs and even coarse sprays are called fumigation when really they are not.

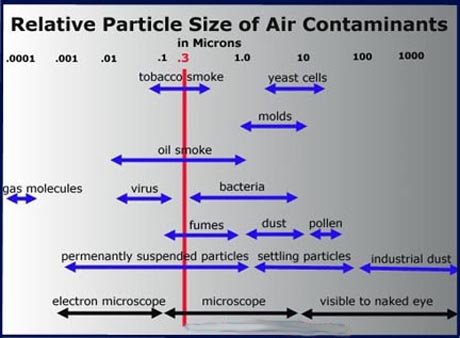

The difference is the size of the particle that is involved in the treatment. Fumigants are gasses, which means that the particle size of the active ingredient is very much smaller than smokes, fogs and sprays.

I often tell my students that smokes, fogs and sprays get on insects, whereas fumigants get in insects.

FYI the red line at 0.3microns is the size of a grain weevil's spiracle at normal lab conditions

This means that fumigants are very penetrative and can get inside a product or item that you are trying to rid of insects, rather than just being lethal to the insects on the surface.

Fumigant gases diffuse as separate molecules that penetrate into and through the material being fumigated. The molecular activity of gases increases with temperature. "Charles' Law" states that for each 1°C increase in temperature gases expand by 1/273.

Thus, the speed of activity of fumigants will increase at higher temperatures

There is also a vast difference in the mode of action of fumigants and insecticides.

Where insecticides almost always affect the nervous system of a target insect, fumigants almost always affect the mitochondrial chain, which means that fumigants affect every cell in the body of the target species. Clearly this is a more effective and efficient method of controlling insect pests.

It must also be mentioned that fumigants are much more toxic than insecticides, which means that much less active product needs to be used and that fumigation should only be attempted by specialist licensed companies like Dealey Environmental.

The Three Stages of Fumigation

This stage is where most of the fumigator's skill will come into play and determine whether the fumigation will be successful or not

The fumigator must abide by strict calculations of the volume of the product or object being fumigated and also the concentration required

A deep knowledge of insects is necessary because many different species of insect have differing susceptibilities to fumigant gases, especially in this day and age where genetic resistance of insects to some fumigants must be taken into account

The successful sealing of the object or product is crucial because all fumigants will need to be held at a consistent concentration over a period of time to have the desired insecticidal effect. Any variation of concentration over time either up or down may cause the fumigation to be unsuccessful.

"If you are not monitoring, you are not fumigating"

These are the words of the late Jan van Someren Graver who was regarded as one of the world's leading fumigation experts.

The monitoring step is often the most important step of the fumigation. Sadly, it is also the one that is most commonly skipped by under-resourced fumigation companies.

All fumigations are subject to Haber's Rule which was first demonstrated by Fritz Haber in the early 1900s and can be summarised as follows:

In this equation C is the concentration of the gas (measured as mass per volumetric unit), t is the amount of time necessary to be exposed to the gas to produce the desired toxic effect, and k is a constant.

This rule is used to calculate concentration time products (CTPs) which once calculated can prove whether a fumigation is working or not.

Reaching a lower fumigant CTP than is the threshold for the target pest species will lead to a failed fumigation.

This has become especially important in the UK where we restrict ourselves to a single application of fumigant gas for any one fumigation on the basis of food safety. And yet, most fumigation companies still leave out this step.

This is often the most dangerous stage of the fumigation where technicians, site personnel and members of the public may be exposed to fumigant gasses.

Ventilation can be done in two ways. Active ventilation uses fans to move the fumigant gas into safe areas or deactivation apparatus where it will no longer pose a threat to human health. Passive fumigation allows the fumigant gas to diffuse into the surrounding areas.

Gasses that are lighter than air, like hydrogen cyanide, may be ventilated according to a Gaussian Plume model. However, fumigants that are heavier than air, like phosphine, sulfuryl flouride and methyl bromide, must be ventilated carefully and constantly monitored until the diffusion of the gas into the surrounding area lets the fumigant gas reach concentrations that no longer pose a risk to human health or the environment.

All fumigation ventilation processes must be subject a generous exclusion zone which is constantly monitored.

How Long does a Fumigation Take?

The exposure time is determined by several factors including temperature, species of insect targeted and fumigant type.

Some common exposure times for fumigants are listed below:

Phosphine: 5-14 days

Hydrogen Cyanide: 24 hours

Sulfuryl Flouride: 24 Hours

Carbon Dioxide: 21-28 days

This is the time that is elapsed between the start of the first stage and the end of the third stage of the fumigation.

In Conclusion

Fumigation is a highly specialised area of pest control that must only be performed by trained, experienced and licensed professionals.

In the UK, to perform any stage of the fumigation listed above, a fumigator must hold the foundation training of Level 3 Award in Safe Use of Fumigants for the Management of Invertebrate Pests- Unit 1

COMBINED WITH

Any one of the following Units which descibes the specialism that the fumigator has chosen and gained experience in:

Unit 2: Carry out procedures for the safe fumigation of freight containers and static containers used as fumigation chambers

Unit 3: Carry out procedures for the safe fumigation of commodities under sheet and bulk grain in grain stores

Unit 4: Carry out procedures for the safe fumigation of silos

Unit 5: Carry out procedures for the safe fumigation of ships' holds

Unit 6: Carry out procedures for safe fumigation of buildings, warehouses, food processing plants and mills

Unit 7: Carry out procedures for the safe fumigation of purpose-built fumigation chambers

Unit 8: Carry out procedures for the safe fumigation of specialist ‘fumigation bubbles'

At Dealey Environmental, we have technicians that hold certification in all of the above Units as well as additional units for aircraft and soil fumigation.

As leaders in the UK fumigation market, whatever your fumigation need, we will be able to get it done.

Contact us for a free consultation

01359 269713 info@dealey.co.uk